USB4 Cable Specifications: The Future of High-Speed Connectivity

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

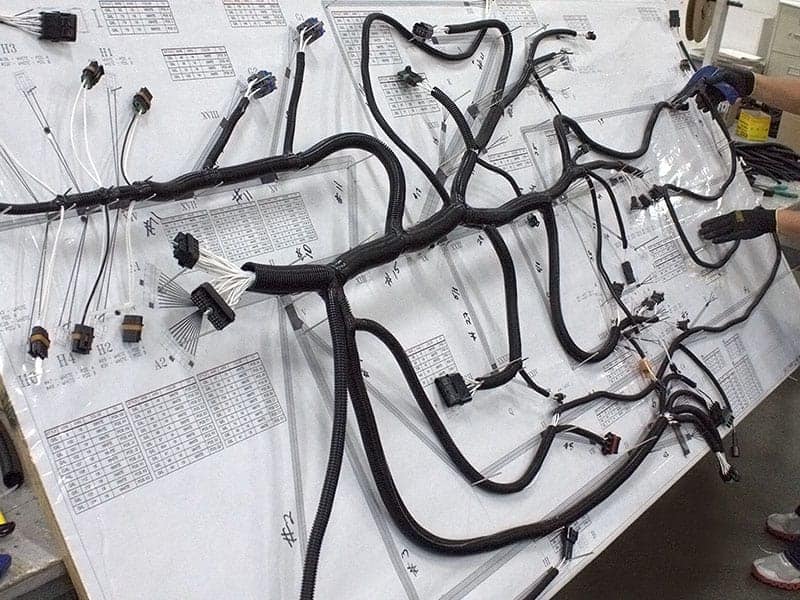

Begin with an introduction to the importance of custom wire harness design in various industries. Emphasize how a well-designed wire harness can lead to improved efficiency, safety, and cost savings. Highlight that avoiding common mistakes is crucial for success.

Discuss how neglecting to consider the environmental conditions (temperature, moisture, chemical exposure) can lead to premature wire harness failure. Provide tips for selecting the right materials and design features to combat these conditions.

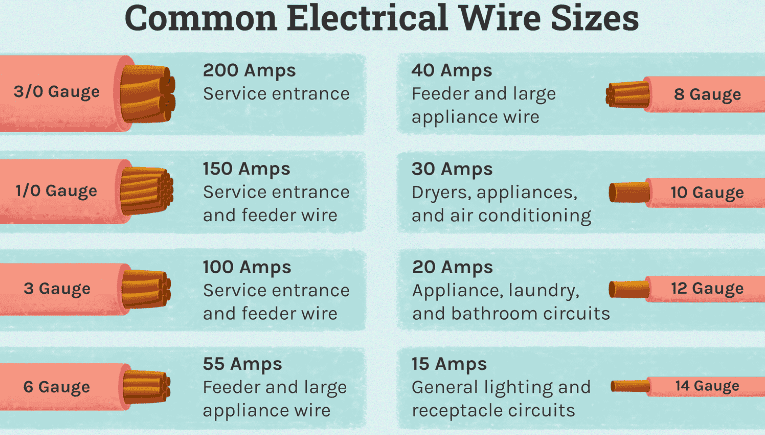

Explain the importance of choosing the correct wire specifications, including size, insulation type, and voltage rating. Illustrate how incorrect specifications can lead to underperformance or safety hazards.

Stress the importance of accurate documentation and labeling for maintenance and troubleshooting. Offer examples of best practices in schematic representation and labeling.

[Insert Video: Step-by-step guide on how to properly document and label wire harnesses]

Highlight the need for comprehensive testing protocols to ensure reliability and safety. Discuss different testing methods and the common areas often missed during testing.

Address the temptation to sacrifice quality for cost savings. Explain the long-term costs of using inferior materials or skipping necessary quality checks.

Wrap up by reiterating the importance of avoiding these common mistakes. Encourage readers to consult with professionals and choose experienced manufacturers to ensure the highest quality in their custom wire harness designs.

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

Understanding the Evolution of USB Connectors In today’s technology-driven world, USB (Universal Serial Bus) connectors are an integral part of

At EDOM Electronics, we take pride in our meticulous approach to manufacturing high-quality USB C to C cables. Today, we’re

WhatsApp us