USB4 Cable Specifications: The Future of High-Speed Connectivity

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

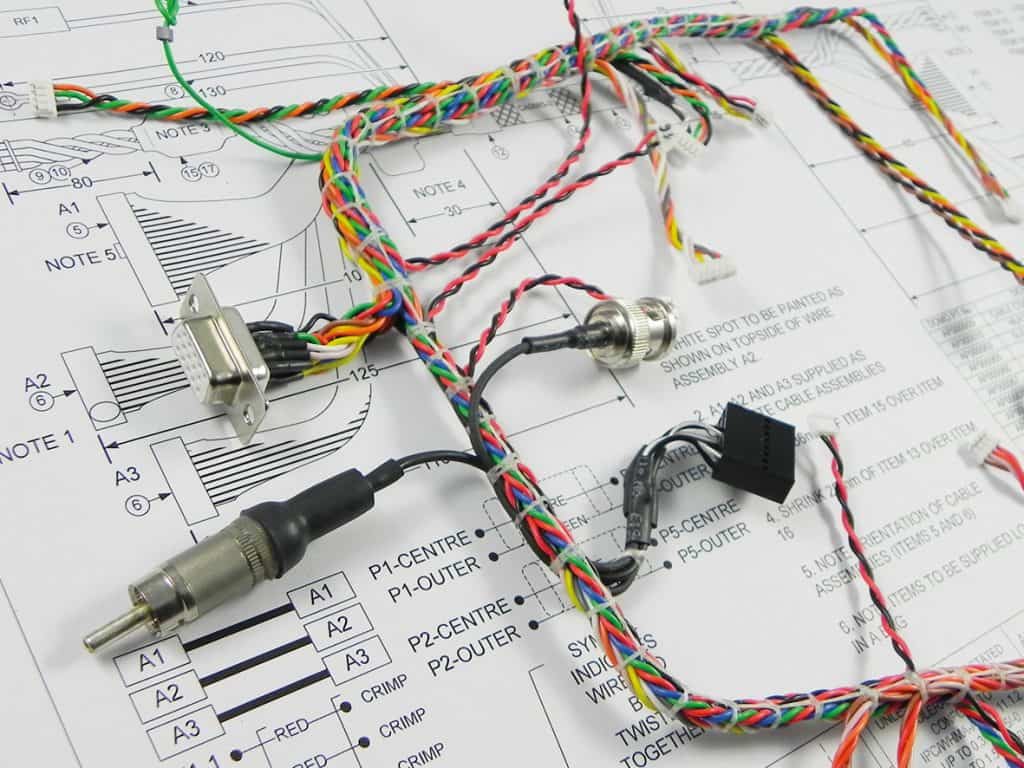

Customization is the process of tailoring a product from the traditional standard to meet the specific needs of an individual or group. This may include changes to the appearance, function, or feel of the product. Customizing cable assembly is a great way to make your product stand out from the rest. There are many different ways of customizing cable assemblies, and this article will list and describe them all! Cable assembly customization can be done for many reasons, but one of the most popular is that consumers always request it. Read on to find out how they’re customized, the common customization requests, and more!

Cable assemblies are customized for different purposes. A few of them are listed below:

This is the most common type of customization and it is done to meet the specific needs of a customer. It may be to make the cable assemblies of right length and thickness as desired by the customer.

In some cases, a company may need to replace an old cable with a new one but may not have access to the original part or specifications. In such cases, they will need to find a supplier that can provide them with a customized cable assembly that matches the old one as closely as possible.

For some companies, their cables need to be environmentally friendly and eco-friendly so they look out for suppliers who offer customizations based on these parameters

For example: If electrical equipment being used by consumers comes into contact with water while plugged in then this could potentially cause electrocution which could lead to injury or even death. Some companies might want a manufacturer of cables assemblies to add protection against water contact, which would then make the cable assemblies safe to use in these conditions.

Certain industries have specific requirements for cable assemblies that are not found in other industries. For example, the medical industry has very stringent requirements for their cables assemblies because of the critical nature of the equipment that they use. Military and aerospace companies also have their own set of specific requirements which need to be met by suppliers when creating customized cable assemblies.

When cables are customized, several factors need to be taken into account. The most important of these include:

This will determine what type of customization is required and what material should be used for the cable assembly. For example, if it is going to be used in an outdoor environment then it needs to be weatherproof and have a higher level of protection from elements like water and dust.

This will determine whether it needs an extra level of protection or not. For example, if the cable assembly is used in a public place then there may be chances that people might tamper with it so adding security features to prevent tampering would be necessary.

This is another important factor that needs to be considered when customizing a cable assembly. If the data transmission rate is high, then the cables need to be made of higher quality materials and should be able to handle more stress

The way in which a cable assembly is customized can vary depending on the supplier. However, there are some general steps that are usually followed:

1. The specifications or requirements provided by the customer are analyzed

This includes understanding what type of material is needed, what length and thickness is required, what type of connectors are needed etc.

2. A prototype is created

This is usually done using the customer’s specifications as a guide. The prototype will then be sent to the customer for approval

3. A manufacturing plan is created

Once the customer has approved the prototype, mass production of the cable assemblies can begin. The supplier will create a manufacturing plan and ensure that all of the necessary machinery and tools are in place to produce the required number of assemblies

Quality control is also an important step during this process and samples from each batch of assemblies are tested to make sure that they meet all quality standards

There are several types of customers who typically request customized cable assemblies:

– Companies who have their own requirements for wire products which are not met by standard off-the-shelf cable assemblies

These companies need to find a supplier who can provide them with customized assemblies specifically for their application. For example, if there is a requirement for an unusual connector type then the would need to create a new connector type

– Industries that have specific requirements that are not found in other industries

Certain industries have specific requirements for cable assemblies that are not found in other industries. For example, the medical industry has very stringent requirements for their cables assemblies because of the critical nature of the equipment that they use

– Companies that require a high level of customization

Some companies might have their own requirements which are not met by standard off-the-shelf cable assemblies. In these cases, they need to find a supplier who can provide them with customized assemblies specifically for their application. For example, if there is a requirement for an unusual connector type then the would need to create a new connector type

There are three ways in which cable assemblies can be customized:

The different types of connectors that are available can be used to create a customized cable assembly. This is usually done when there is a specific requirement from a customer for a certain type of connector. For example, some companies may need a circular connector instead of the standard rectangular one so this change can be made without any problems.

Another way to customize cable assemblies is by altering their length. This can be helpful when an exact size is not available or if it needs to match another existing cable. It should be noted that while shortening cables is easy, lengthening them is not so simple and requires a high level of technical expertise.

Adding features to cable assemblies can also be done in order to customize them according to specific requirements from companies. These include adding security measures like tamper-proofing or anti-tampering features which would ensure that the products cannot easily be altered by customers. Other common additional feature includes flame retardant properties, electromagnetic interference protection etc.

The color of the cable jacket is also something which can be customized in order to make it easier to identify them. This is especially helpful when a large number of cables need to be used and they need to be quickly identified. The different colors can also help with branding exercises or identifying which department or division the cable belongs to.

Adding labels or logos to cable assemblies can also be done in order to customize their look and give a more professional appearance. This is especially important when the cables are being used for promotional activities which might include trade shows, exhibitions etc., where they will need an outwardly appealing design. In addition, adding company logos helps with identifying products from different suppliers so that if there is any problem found about a particular product then it becomes easy to pinpoint its originator.

There are several benefits associated with customizing cable assemblies:

– Customized cable assemblies are less likely to break down even in high voltage applications.

– Customized cables make your computer look more professional.

– Being able to customize a cable assembly is empowering because it allows you to be in control of the cable types you acquire.

– Customized cable assemblies may be more flexible depending on the material used in their construction.

When choosing between suppliers for your custom cable assemblies, there are several things you need to consider before making a final choice. They include:

Go through the supplier’s portfolio to check for their past wire harness projects and see if they have ever manufactured products similar to yours. If so, then you can use this information to find out what customization options were offered in those cases and whether or not there is a good chance that these will be provided by them again.

How quickly do you need the custom cables? Suppliers usually have different manufacturing capabilities and turnaround times for completing custom requests. Make sure to factor this into your decision-making process.

Price is always an important consideration when making any purchase and it is no different when choosing between suppliers of customized cable assemblies. However, don’t let price be the only deciding factor as cheaper alternatives may not always offer the same level of quality or customization as more expensive ones. Be sure to settle for a supplier that offers a cost effective solution -which means you are getting the highest quality desired at a reasonable price.

This should be one of the most important factors when deciding on a supplier of your customized wire and cable assemblies. Always ensure that the supplier has a competent engineering team, and a good reputation for quality products and services before committing to them.

This post has covered the basics of what custom cable assemblies are and why they are needed. Now it is time for you to take action! If you want custom wire harnesses and cable assemblies, we recommend Edom Electronics. They provide low-cost OEMs with high quality precision cabling from start to finish. Its team will work with your engineers on every aspect of the design process, ensuring that they create a product that meets all of your specifications while still meeting budget requirements.

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

Understanding the Evolution of USB Connectors In today’s technology-driven world, USB (Universal Serial Bus) connectors are an integral part of

At EDOM Electronics, we take pride in our meticulous approach to manufacturing high-quality USB C to C cables. Today, we’re

WhatsApp us