USB4 Cable Specifications: The Future of High-Speed Connectivity

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

At EDOM Electronics, we take pride in our meticulous approach to manufacturing high-quality USB C to C cables. Today, we’re giving you an exclusive look at the detailed steps involved in our cable assembly process, from wire cutting to packaging. Our commitment to precision and quality ensures that every cable we produce meets the highest standards, ready to serve the needs of our B2B clients worldwide.

The journey of each USB C to C cable begins with precision wire cutting. Using advanced automated cutting machines, we ensure that each wire is cut to the exact length required. This precision is crucial for maintaining uniformity and performance in the final product.

After cutting, the insulation at the ends of each wire is carefully stripped away to expose the conductive copper. High-precision stripping machines perform this step, ensuring that the wires are not damaged and maintain their integrity for optimal conductivity.

Once the wires are stripped, they are divided and arranged into specific groups based on their function within the cable. This step ensures that power, data, and ground wires are properly separated and organized, which is critical for the subsequent assembly stages.

To enhance connection stability, the crimped wires undergo a soldering process. Solder is applied to the joints to reinforce the connection between the wire and the connector. This step provides additional mechanical strength and ensures long-term reliability.

The crimped and soldered wires are then placed into molds for the overmolding process. This step involves encasing the wire ends and connectors in a protective plastic layer. Overmolding strengthens the connection points and provides strain relief, preventing damage from bending and pulling.

The assembly continues with the application of shielding to protect against electromagnetic interference. A layer of aluminum foil or braided copper is wrapped around the wires. This shielding is crucial for maintaining signal integrity, especially in environments with high levels of electronic noise.

The shielded wires are then enclosed in a durable outer sheath made from flexible yet robust materials such as PVC or TPE. This outer layer provides additional protection against physical damage and environmental factors, ensuring the cable’s longevity and reliability.

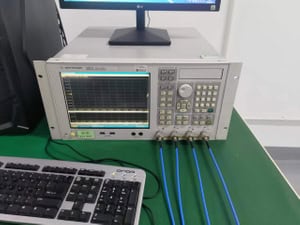

Each assembled cable undergoes rigorous quality testing to ensure it meets EDOM Electronics’ high standards. Tests include checking electrical performance, signal integrity, mechanical strength, and compatibility with various devices. Only cables that pass all these tests are approved for packaging.

Approved cables are carefully coiled and packaged. We use eco-friendly packaging materials that protect the cables during transit and are easy for our B2B clients to handle. Each package includes relevant product information and usage instructions, ensuring that our clients receive the best possible experience.

Finally, the packaged cables are prepared for shipment. We coordinate with trusted logistics partners to ensure timely and safe delivery to our clients worldwide. Our efficient shipping processes are designed to minimize lead times and meet the schedules of our B2B clients.

At EDOM Electronics, our meticulous cable assembly process ensures that every USB C to C cable we produce is of the highest quality. By sharing our detailed assembly process, we hope to give you a better understanding of the craftsmanship and dedication that goes into every product we deliver to our B2B clients around the globe.

At EDOM Electronics, we are committed to delivering top-notch USB C to C cables that meet the highest standards of quality and reliability. Partner with us to ensure your business gets the best in connectivity solutions.

Contact us today to discuss your bulk order needs and discover how our customized solutions can elevate your products. Let’s build a stronger connection together!

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

Understanding the Evolution of USB Connectors In today’s technology-driven world, USB (Universal Serial Bus) connectors are an integral part of

The USB-C connector and USB-C cables are revolutionizing the way we connect and power our devices. As technology advances, these

WhatsApp us