USB4 Cable Specifications: The Future of High-Speed Connectivity

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

Introduction

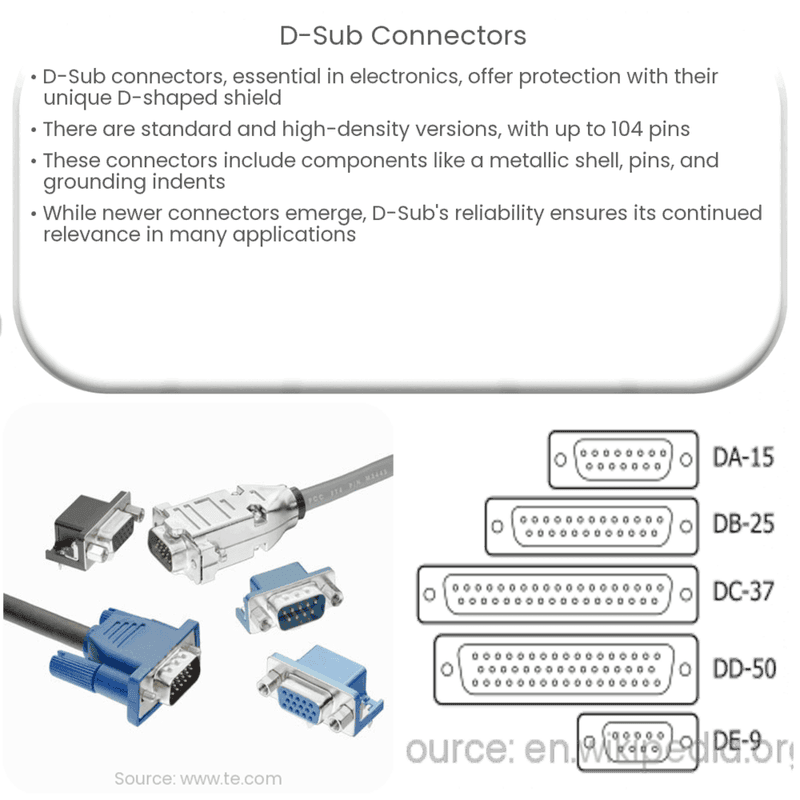

D-Sub connectors, short for D-Subminiature connectors, have been a cornerstone in the realm of electronic connectivity for decades. Despite the advent of newer technologies, their versatility and reliability have ensured their continued relevance in modern electronics. This article delves into the enduring significance of D-Sub connectors, exploring their types, applications, and how they adapt to the ever-evolving demands of the electronics industry.

Understanding D-Sub Connectors

D-Sub connectors are characterized by their distinctive D-shaped metal shield, which provides mechanical support and ensures proper alignment through a polarized interface. This design minimizes the risk of connection errors, protecting the integrity of the data and power being transmitted.

Types of D-Sub Connectors

D-Sub connectors come in various configurations, catering to a wide range of applications:

Applications of D-Sub Connectors

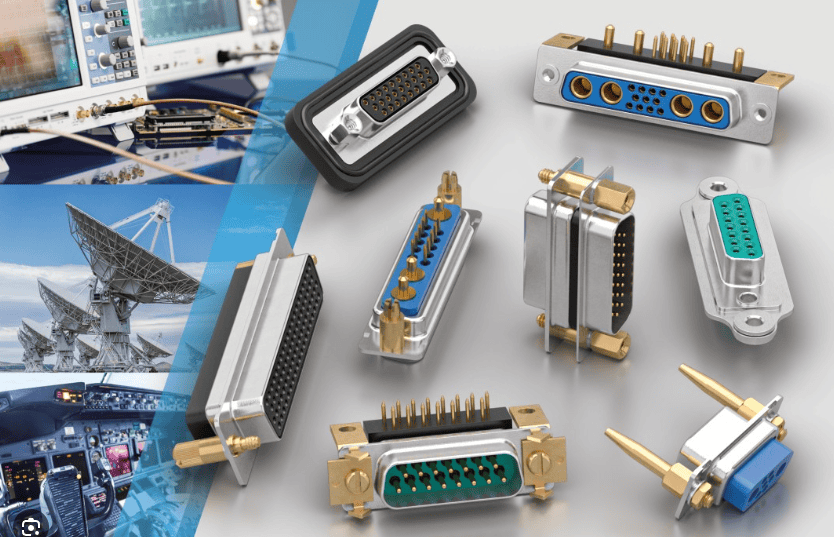

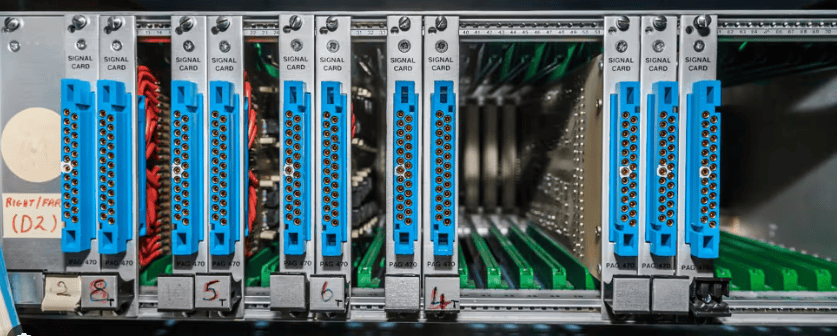

Despite predictions about their obsolescence, D-Sub connectors are used in a myriad of modern applications:

Advantages of D-Sub Connectors

The continued popularity of D-Sub connectors can be attributed to several advantages:

Future of D-Sub Connectors

While newer technologies are emerging, D-Sub connectors are evolving to meet the demands of modern electronics. Innovations include smaller footprints, higher-density configurations, and integrated signal and power contacts. The development of environmentally friendly materials and designs is also ensuring that D-Sub connectors remain relevant.

Conclusion

D-Sub connectors exemplify the balance between traditional reliability and modern innovation. Their continued adaptation ensures they remain integral components in the electronics industry, from industrial machinery to advanced computing systems. As technology evolves, the versatility and durability of D-Sub connectors will continue to make them a preferred choice for a wide range of applications.

Are you in search of reliable, versatile connector solutions for your electronic applications? Explore our extensive range of D-Sub connectors. For queries or more detailed information, don’t hesitate to leave an inquiry.

Introduction As technology continues to evolve, the demand for faster, more efficient connectivity solutions has become critical for businesses and

Understanding the Evolution of USB Connectors In today’s technology-driven world, USB (Universal Serial Bus) connectors are an integral part of

At EDOM Electronics, we take pride in our meticulous approach to manufacturing high-quality USB C to C cables. Today, we’re

WhatsApp us