10 Top Wire Harness Manufacturers in China

China’s booming electronics sector is supported by a robust network of wire harness manufacturers, critical to various industries including automotive,

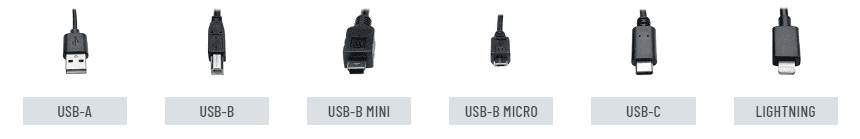

At Shenzhen EDOM Electronics Co., Ltd., a leading USB connector factory, we welcome audits from our customers as a testament to our commitment to transparency and quality. This guide is designed to assist procurement professionals in conducting a comprehensive audit of USB connector manufacturers like ours. By delving into the intricacies of the audit process, we ensure that every component we produce meets the highest industry standards, contributing to the reliability and performance of your electronic products.

Begin with thorough preparation to understand the specific needs and standards for USB connectors:

Upon arriving at the factory, start with a review of all critical documentation:

A meticulous walkthrough of the factory is essential to understand the manufacturing processes:

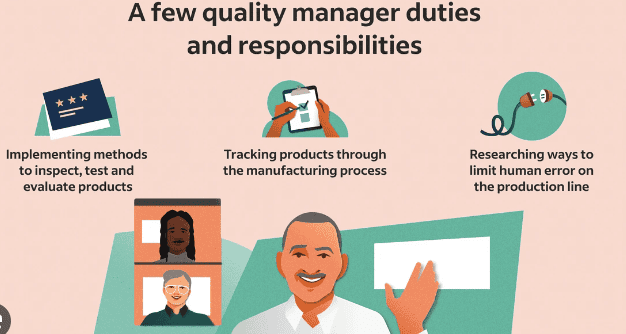

Deep dive into the quality control systems implemented by the factory:

Engage with the factory staff to understand their level of training and expertise:

Evaluate the storage and final handling of the USB connectors:

Conclude the audit with a comprehensive report and a feedback session:

Auditing a USB connector factory like Shenzhen EDOM Electronics Co., Ltd. requires a deep understanding of the manufacturing process and a keen eye for detail. Through rigorous audits, we not only demonstrate our adherence to the highest standards but also foster a culture of continuous improvement and transparency. For potential customers looking to ensure the quality of their electronic components, our doors are always open.

Call to Action: To learn more about our processes or to schedule an audit, visit Shenzhen EDOM Electronics.

China’s booming electronics sector is supported by a robust network of wire harness manufacturers, critical to various industries including automotive,

Introduction The advent of USB Type-C connectors has revolutionized the landscape of connectivity in modern electronic devices. Their compact size,

Introduction D-Sub connectors, short for D-Subminiature connectors, have been a cornerstone in the realm of electronic connectivity for decades. Despite

Want to get our timed product and solution updates?

Please subscribe to our mailing list.

WhatsApp us